This article delves into the impact refrigeration systems have on various industries and highlights the widespread use of vapor compression systems in particular sectors. Explore the development of refrigeration technology and understand the operational principles of well-known systems as well as the market dynamics influencing consumer choices. Get insights into the obstacles that manufacturers encounter, such as regulations and economic demands while exploring recent technological innovations that offer improved efficiency and sustainability. Learn suggestions for enhancing refrigeration performance. This article offers insights to help the ever-changing refrigeration industry.

Overview of Refrigeration Equipment

Refrigeration units play a role in our modern society by aiding various industries in preserving goods and creating optimal storage conditions through the cooling of designated areas via the removal of heat using refrigerants that go through multiple stages of heat absorption and release in the refrigeration process.

Historical Development of Refrigeration Technology

It had gone in a few directions as refrigeration technology has progressed. It started gathering ice and other natural ways of preserving food and other articles. Nowadays, though complicated, these methods have been adopted. The very first to be developed was that using vapor compression cycles in the 1800s. Their efficiency has since improved with improvements in materials and engineering, hence more applications of these.

Types of Refrigeration Systems Available in the Market

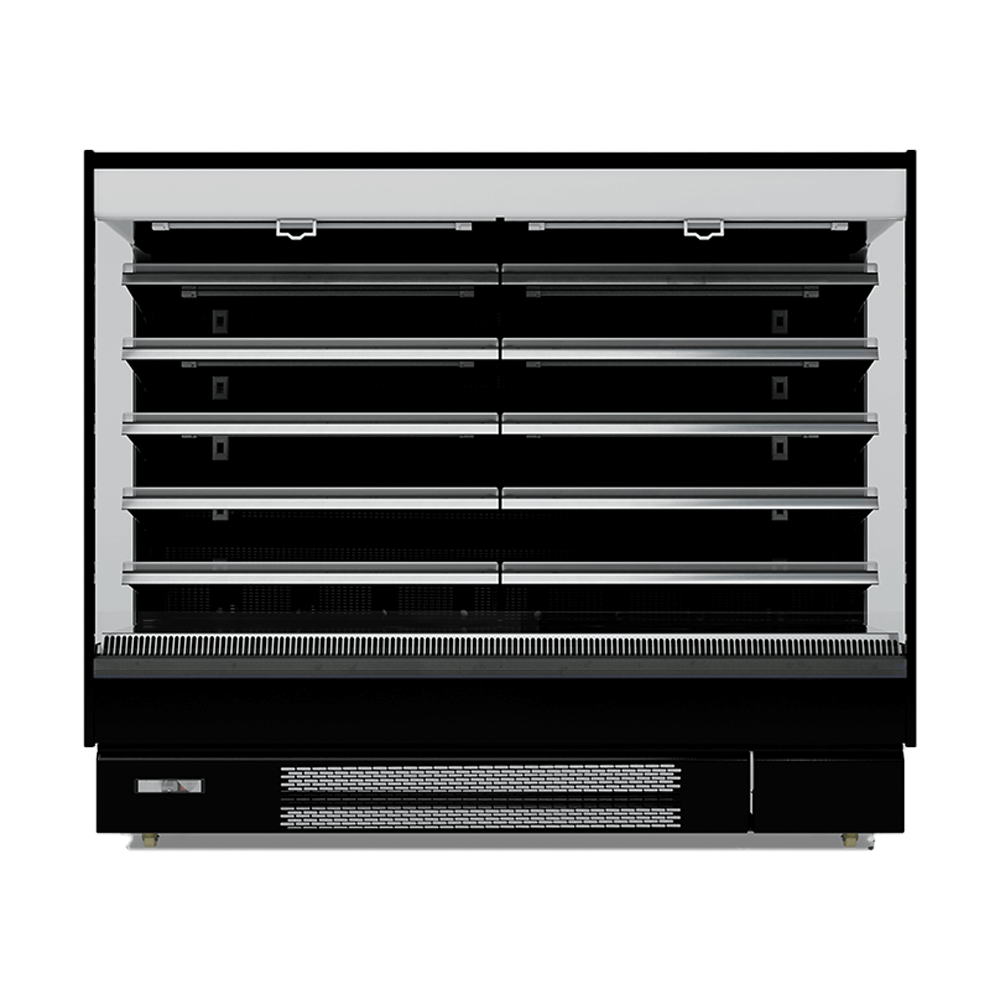

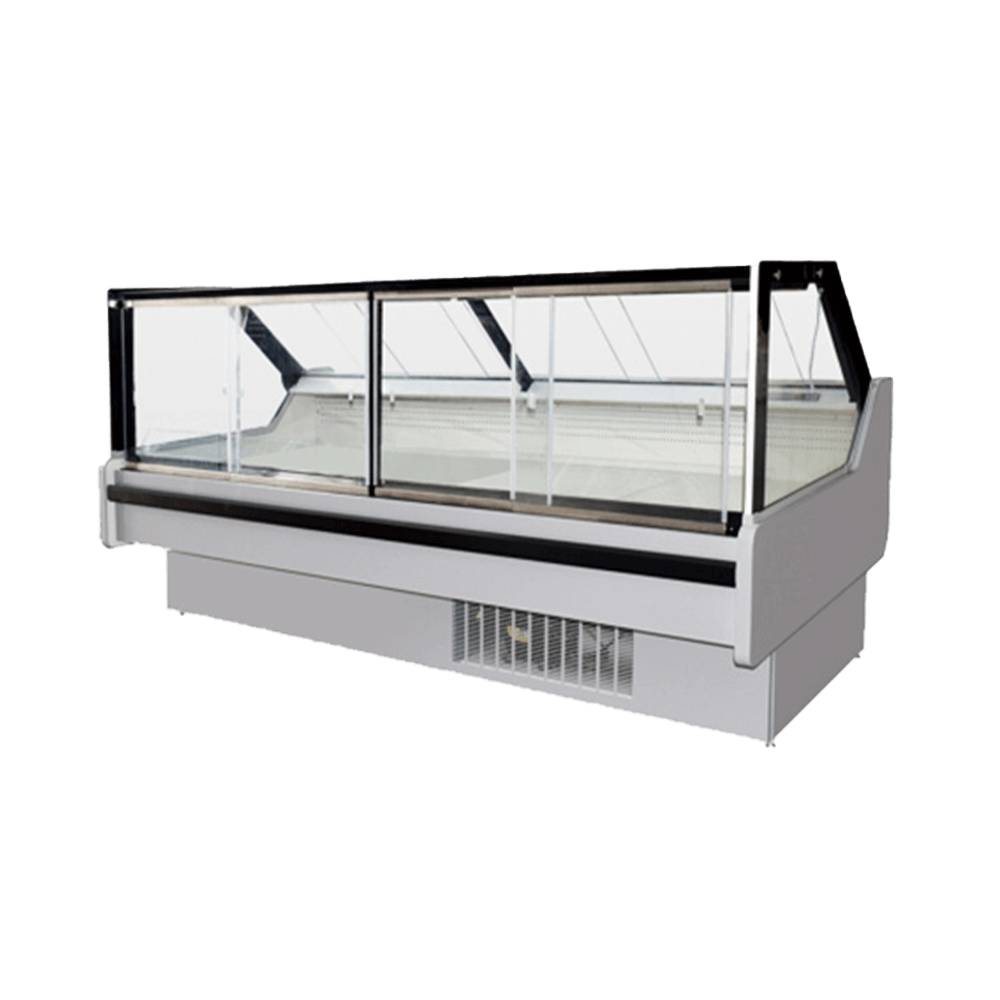

There are several varieties of refrigeration systems, each serving the purpose intended in a different design. Their sizes, complexities, and technologies widely vary, making it very relevant to understand the differences for purposes of making an appropriate choice for particular needs.Vapor Compression Systems

In the refrigeration industry scene vapor compression systems are widely utilized due to their efficiency and versatility. This mechanism involves compressing a refrigerant that absorbs heat as it evaporates under pressure and releases heat when it condenses under high pressure. These systems are frequently found in commercial settings being used for purposes like air conditioning units, refrigerators and large-scale industrial cooling arrangements.

Absorption Refrigeration Systems

Absorption cooling systems offer a way to use heat for cooling than depending entirely on mechanical energy input distinguishing them from conventional refrigeration systems. They typically utilize ammonia or water as coolant. Are commonly used in industrial settings and remote locations with limited or unreliable access to electricity.

Thermoelectric Refrigeration Systems

Such are thermoelectric coolers-those classes of devices characterized by solid-state construction without moving parts or refrigerants involved in the process. Basically, the thermoelectric cooler is based on the operational principle that a temperature difference between two materials generates electricity. Thermoelectric coolers, less efficient compared with vapor compression systems, are on demand because they are compact and noisy operation-free, which may be ideal in portable coolers or electronics cooling.

Market Trends in Refrigeration Equipment

The commercial refrigeration market is one of dynamism and growth, this is evident through the growth in dining out and the demand for convenience foods. This increase pushes the demand for reliable refrigeration equipment. The market has consumer preferences and concerns regarding energy efficiency and environmental sustainability that influence its conditions.

Technological Advancements Driving Growth

The demand for refrigeration equipment is on the rise thanks to advancements in the industry. Innovations such as refrigeration systems integrated with technologies offer better energy efficiency and remote monitoring capabilities. Additionally, the development of eco-refrigerants aims to reduce greenhouse gas emissions while maintaining optimal performance levels.

Consumer Preferences and Demand Shifts

In today’s market, consumers are leaning towards friendly energy options for refrigeration equipment leading to a shift in demand trends and influencing manufacturers to focus on sustainable products that maintain performance quality while adhering to regulations.

Understanding the intricacies of refrigeration systems provides perspectives into their extensive utilization in the market and how they are evolving due to technological advancements and consumer choices. With industries pushing limits through creativity we anticipate witnessing the emergence of more efficient and eco-friendly solutions to cater to diverse requirements in global markets.

Challenges Facing the Refrigeration Industry

While the market for commercial refrigeration is expanding, it is also fraught with certain challenges. These include regulations regarding the environment, high costs, and the requirement for continuous innovation to meet changing consumer and industry demands.

Environmental Regulations and Compliance

The refrigeration sector is struggling to meet environmental regulations designed to lessen the environmental impact of refrigerants on climate change issues. The industry is required to switch from substances like CFC and HCFC to refrigerants with global warming potential (GWP) to comply with these rules. This transition demands an investment in research and development to ensure compliance without compromising efficiency. Companies are faced with navigating through regulatory areas that demand substantial time and resources for effective compliance.

Cost Considerations and Economic Factors

Economic factors play a role in shaping the market for refrigeration equipment. The costs of materials such as metals and refrigerants directly impact production costs. Additionally, varying energy prices can influence end users operational costs. Which in turn affects their purchasing decisions. The industry encounters the difficulty of striking a balance between affordability and technological advancement. Manufacturers strive to offer prices while also emphasizing innovation and sustainability through strategic planning and effective resource management.

Future Prospects for Refrigeration Equipment

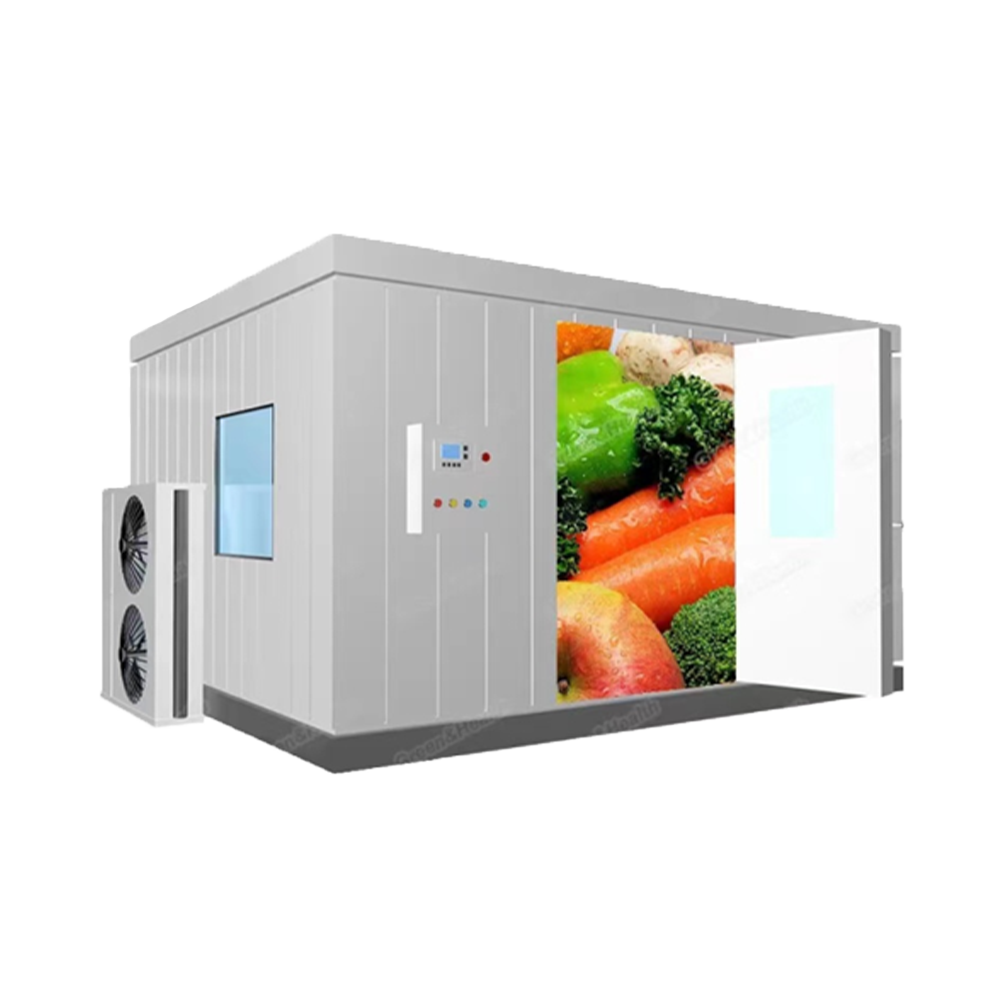

In the future, refrigeration will also continue to develop toward energy efficiency and intelligent functions. You will continue to see an increase in remote monitoring and management for optimal performance and timely maintenance.

Potential Developments in Refrigeration Technology

The future advancements in refrigeration technology appear to present opportunities that could lead to changes in the industry scene. The progress in materials science and engineering is expected to yield heat exchangers and compressors that will enhance the overall performance of systems. Incorporating intelligence (AI) and machine learning algorithms into refrigeration systems is thought to optimize energy usage patterns and enhance predictive maintenance methods resulting in decreased downtime and extending the lifespan of the equipment. Furthermore pioneering investigations into cooling methods such as refrigeration is opening up possibilities for potential progressions that could revolutionize conventional approaches.

Implications for Industry Stakeholders

The recent advancements in technology are revolutionizing the landscape for professionals in the refrigerator industry these days. Businesses must stay abreast of consumer preferences by adopting technologies that prioritize eco-friendly and sustainability – don’t you think? Retailers and suppliers ought to familiarize themselves with the product offerings to effectively communicate the benefits they offer to their customers.

In today’s evolving market environment, different stakeholders must collaborate to promote innovation and address challenges related to regulations and economic requirements with determination and purpose. By fostering teamwork among industry participants including producers, researchers, policymakers and customers the field can set the stage for a tomorrow where refrigeration systems not only meet but exceed expectations in terms of efficiency, dependability and environmental sustainability.

A Reliable Island Freezer Supplier: Shandong Create Refrigeration Co., Ltd.

Shandong Create Refrigeration Co., Ltd. offers refrigeration solutions, tailored to meet the specific needs of your business including coolers, island freezers and custom refrigeration systems – all designed to deliver exceptional performance and reliability that you can depend on. With a focus on sustainability and innovation, Create Refrigeration assures that your cooling arrangements are well-equipped to address the demands of today’s changing landscape.

FAQs

1. What type of refrigerant is typically utilized in cooling systems?

Refrigerating systems operating within the temperature range of +6° to 29°C commonly make use of fluorinated gases referred to as HFCs with the selection depending on the particular equipment and its intended use.

2.How often should I clean the fridge coils?

Keep your refrigerator coils cleaned once every month.

3.For how many years does the vapor compression refrigeration system survive?

A well-managed Vapor compression refrigeration system could last for 15 to 20 years.

4.Are some types of refrigeration systems more friendly to the environment in the future?

It could also be greener, depending on the type of energy they use, to use systems.