Magnetic cooling operates by exploiting the phenomenon where certain materials heat up when exposed to a field and subsequently cool down upon removal from it offering a potential alternative for refrigeration systems that eliminate the necessity, for refrigerants or compressors.

Refrigeration systems play a role in the modern technological environment by impacting various sectors such, as food preservation and manufacturing operations. The knowledge of the four types can enhance your appreciation of their applications and the benefits they provide.

The Role of Refrigeration Systems in Modern Technology

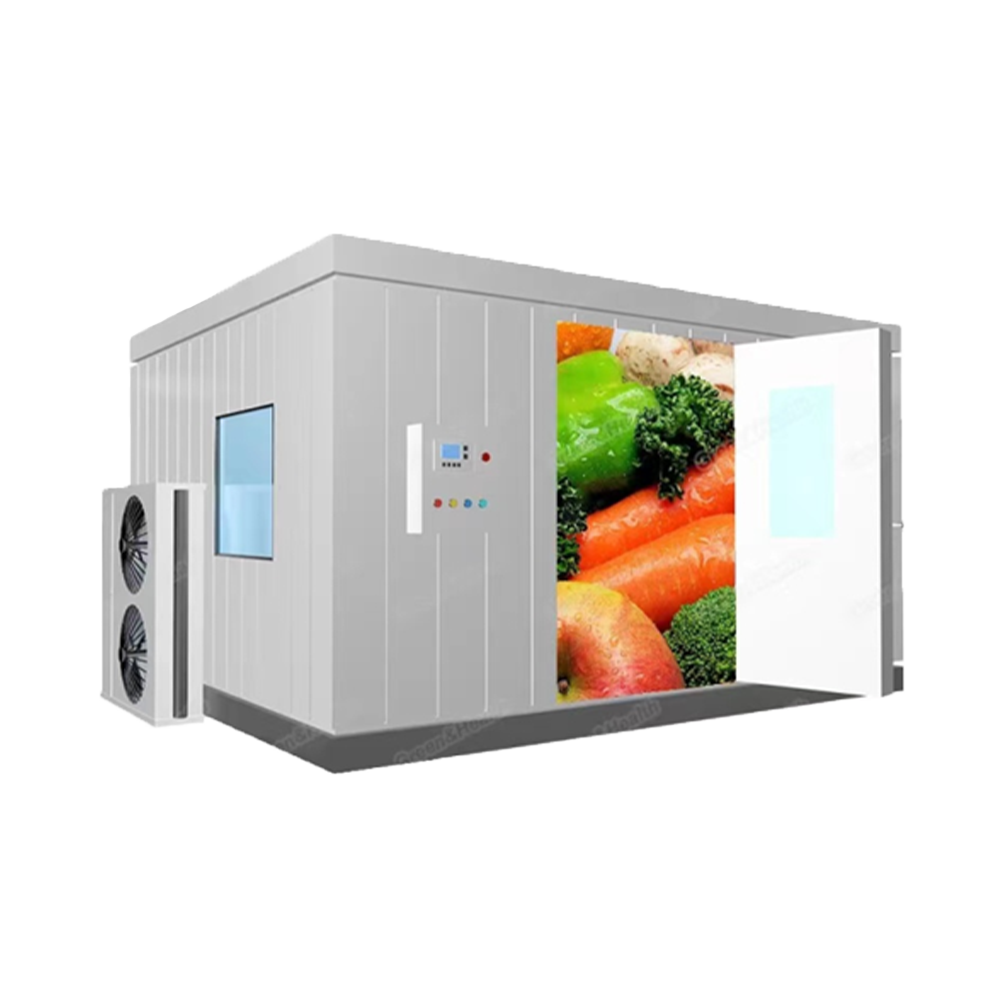

Refrigeration systems are essential in today’s world. They help preserve items and support complex chemical processes that are vital for storage and production in industries, like healthcare and food and beverage manufacturing.

Overview of the Four Main Types

The four main types of refrigeration systems are vapor compression units, absorption systems, thermoelectric coolers, and evaporative cooling devices. Each system has features tailored to different requirements and uses.

How Does Vapor Compression Refrigeration Work?

The use of vapor compression refrigeration is common because of its effectiveness and versatility in environments.

Components and Functionality

This arrangement includes four components; compressor, condenser, expansion valve, and evaporator. The procedure begins with the compressor boosting the gas pressure; it then travels through the condenser to lower its temperature and change into a form; next in line is the expansion valve that lowers the refrigerant pressure before it goes into the evaporator to soak up heat and revert, to a gaseous state. This process repeats to uphold the desired temperatures.

Applications in Various Industries

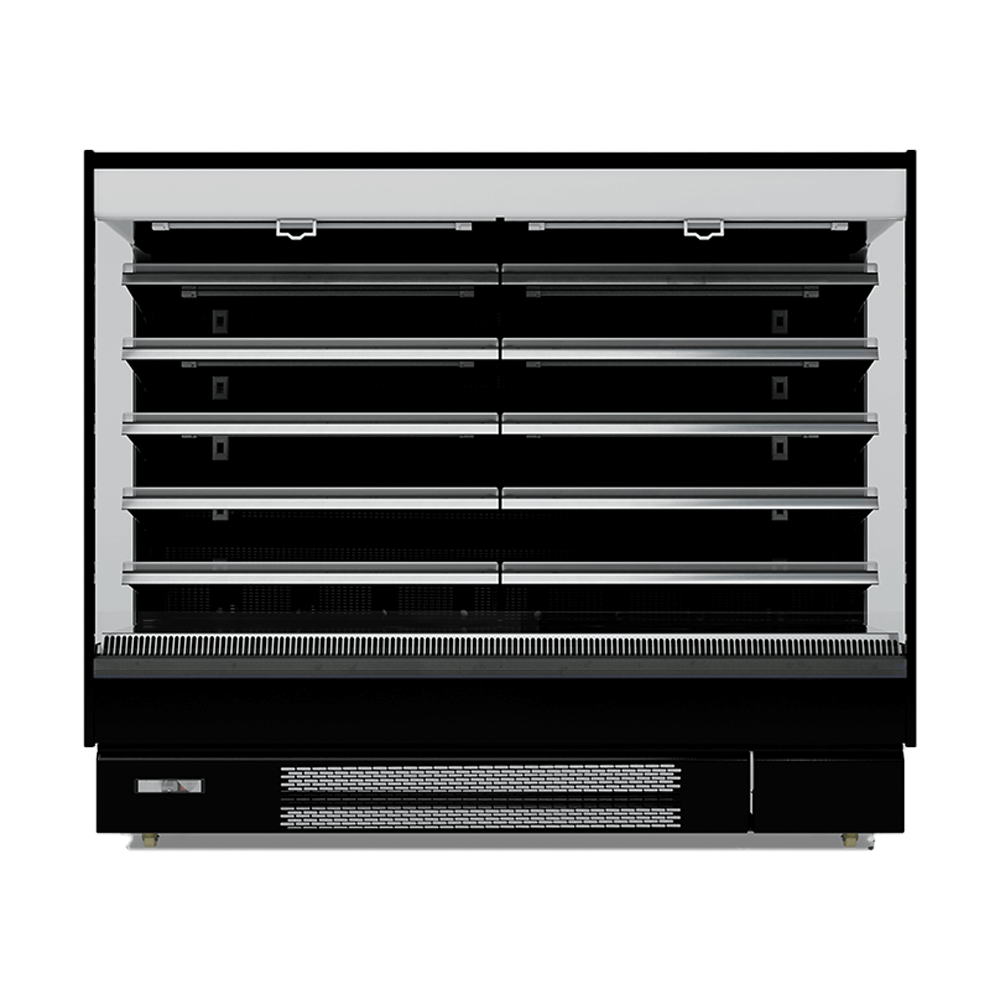

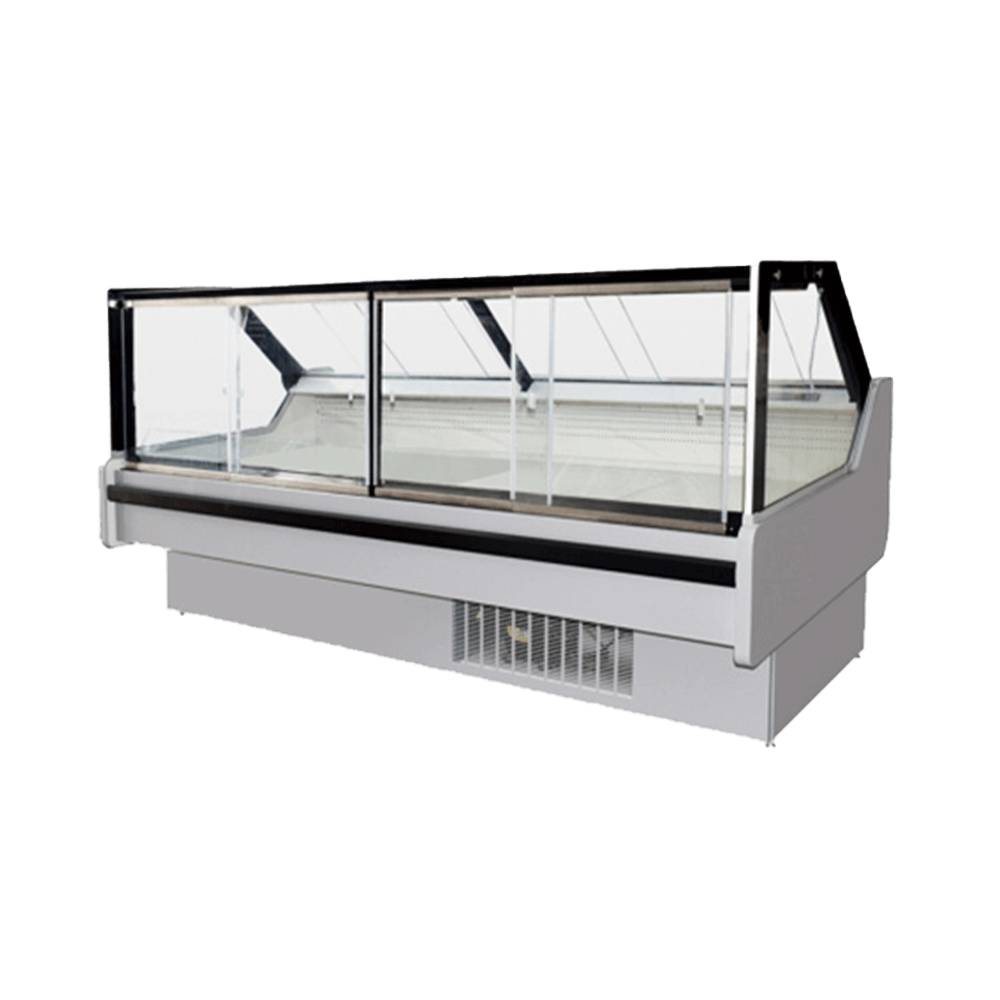

Industrial and Commercial Use Cases

In both commercial settings alike, vapor compression systems are widely used. For instance, in industries such as pharmaceutical and food processing, they play a role in maintaining product quality by keeping them at precise temperatures. Moreover, these systems are essential for powering air conditioning units in office buildings and retail spaces.

For details regarding the implementation of these systems, in various contextsand situations, visit Create Refrigeration.

What Is Absorption Refrigeration?

Using heat as an energy source of electricity absorption refrigeration presents a different method to consider.

Mechanism of Absorption Systems

The operation of these systems hinges on a heat supplier to power the cooling process. A mixture containing a substance soaks up the refrigerant gas released from the evaporator. By heating this mixture enough to separate the refrigerant from the absorbent material, the refrigerant can be condensed in the condenser before circling back to the evaporator for reuse.

Industrial Relevance

Absorption cooling is commonly used in settings with waste heat or limited access to electricity, making it a popular choice for industries, like petrochemical plants seeking to maximize the efficient use of surplus thermal energy.

How Do Thermoelectric Cooling Systems Operate?

Thermoelectric cooling uses semiconductor materials to generate a temperature contrast by passing a current through them.

Advantages of Thermoelectric Systems

These small systems provide temperature regulation without any moving components or cooling agents, making them perfect for tasks, such as cooling electronic devices or portable coolers.

What Is Evaporative Cooling?

Evaporative cooling occurs naturally by using the evaporation of water to lower the temperature of the air.

Practical Applications

In regions with humidity levels like deserts or arid areas where moisture is scarce and the air is dry and warm in such places as homes or farm storage spaces, this approach works well for cooling purposes while also being eco-friendly due to its reliance on natural mechanisms that help keep spaces cooler without using excessive energy.

Check out the options available at OEM Create Refrigeration for personalized solutions that cater to custom designs or OEM specifications.

Why Is Absorption Refrigeration Gaining Popularity?

Absorption cooling is gaining traction for its feature of using heat rather than electricity as a sustainable and effective solution in certain environments.

Principles Behind Absorption Systems

Absorption systems work by utilizing heat to assist in the refrigeration process. They rely on an absorbent substance that traps vapors released from the evaporator. When heat is introduced into the system, it causes the separation of the refrigerant from the absorbent enabling it to condense and go back to the evaporator. This approach eliminates the necessity for compressors, making it a suitable choice for settings with excess waste heat or limited access to electricity.

Advantages Over Traditional Methods

Environmental and Economic Benefits

Absorption refrigeration offers benefits for the environment by cutting down on electricity usage and utilizing waste heat to reduce greenhouse gas emissions effectively. From a standpoint, these systems can lead to cost savings in sectors, such as petrochemicals and manufacturing by making use of surplus thermal energy that would otherwise go to waste.

What Sets Thermoelectric Refrigeration Apart?

Thermoelectric cooling is notable for its utilization of semiconductor materials to generate a temperature difference through the flow of current and provides distinct advantages compared to conventional systems.

Mechanism of Thermoelectric Cooling

This setup works by sending a current through thermoelectric modules made of semiconductor materials that creates a temperature contrast across the module; cooling on one side and heating on the other side effectively without any moving parts or refrigerants involved, making thermoelectric cooling extremely reliable and low maintenance.

Specialized Uses and Benefits

Suitability for Compact and Portable Solutions

Thermoelectric systems work well in situations that need size and easy transportability due to their ability to control temperature accurately and are perfect for cooling electronic gadgets like laptops or medical gear where space and mobility matter most. These systems are also valued for their operation and long-lasting nature, in specific industries.

For more insights into custom solutions or OEM requirements tailored to specific needs, explore OEM Create Refrigeration.

Can Magnetic Refrigeration Revolutionize the Industry?

Magnetic cooling is a technology that has the promise to revolutionize how refrigeration works in the future.

Fundamentals of Magnetic Cooling

Magnetic cooling works based on the concept of the effect in which specific materials heat up when in contact with a magnetic field and cool down once removed from it. This process can be utilized to create refrigeration systems without the need for refrigerants or compressors.

Potential for Innovation in Energy Efficiency

Magnetic refrigeration systems offer an advantage in terms of energy efficiency by cutting down on energy consumption in comparison to traditional methods as they remove the necessity for mechanical parts and refrigerants. This enhanced efficiency can result in cost savings and environmental advantages, which make them a compelling choice for use in both industrial and residential settings.

Future Prospects and Challenges

Although magnetic refrigeration shows advantages in theory and practice alike, various hurdles need to be overcome for it to become widely accepted. One major challenge lies in creating materials that are both cost-effective and efficient. Furthermore, expanding these systems for use in businesses necessitates additional investigation and creativity.

Despite these obstacles, the possibility of cooling lowering energy usage and environmental effects makes it an attractive field for further study. As progress is achieved, this innovation could influence the evolution of refrigeration methods in different industries.

How Do You Choose the Right System for Your Needs?

Selecting the refrigeration system is crucial, for ensuring optimal performance and meeting requirements. It’s important to consider various aspects to assist you in making a knowledgeable decision.

Factors to Consider When Selecting a System

When choosing a refrigeration system for your needs and to meet regulations and operational requirements effectively consider factors like its purpose of use and environmental effects, alongside energy efficiency and cost effectiveness.

Tailoring Solutions for Specific Applications

Refrigeration systems are highly adaptable to suit needs and purposes, be it for industrial use or specialized settings, such as laboratories or commercial cooling requirements.

Customization Options with Create Refrigeration

Create Refrigeration provides solutions tailored to various needs by working closely with specialists to develop systems that seamlessly blend with current operations to boost overall performance and efficiency levels. Explore a range of customized design possibilities that address individual needs and specifications.

If you’re interested in Original Equipment Manufacturers (or OEM companies), Create Refrigeration can help by providing OEM services to tailor products to meet needs and industry standards. When considering these factors. Exploring the various customization options at your disposal. You can select a refrigeration system that meets requirements and is adaptable, to future demands.

What Role Does OEM Play in Refrigeration Systems?

OEM, or Original Equipment Manufacturer, plays a pivotal role in the development and innovation of refrigeration systems. By collaborating with OEMs, companies can enhance their product offerings and stay competitive in a rapidly evolving market.

Understanding OEM in the Context of Refrigeration

In the field of refrigeration technology, OEM stands for equipment manufacturers who create parts or systems sold by a different company under its brand. This partnership enables the use of skills and assets, resulting in top-notch products tailored to meet unique market demands.

Benefits of OEM Partnerships

Partnering with an OEM offers numerous advantages. Businesses can leverage cutting-edge technologies and manufacturing resources without the need for investments in research and development through such partnerships. This cooperation may result in reduced costs for product launches and enhanced product standards. Furthermore, team-ups, with OEMs typically offer design and production flexibility enabling the creation of bespoke solutions to meet customer needs.

Enhancing Product Development and Innovation

OEM collaborations are instrumental in driving innovation within the refrigeration sector. Companies can explore new technologies and design concepts that enhance system performance and efficiency.

Working with an OEM can also facilitate the integration of cutting-edge features into refrigeration systems. This includes advancements in energy efficiency, environmental sustainability, and smart technology integration. As a result, businesses can offer products that not only meet current industry standards but also anticipate future trends and demands.

Businesses seeking to delve into OEM opportunities can benefit from Create Refrigeration. It offers a wealth of expertise and experience in developing custom refrigeration solutions tailored to meet needs and objectives.

By understanding the vital role of OEMs in refrigeration systems, you can make informed decisions. Start a partnership that will drive growth and innovation within your organization.