It is required to maintain an environment in most places such as keeping food in a supermarket or drinks in a bar and also keeping sensitive machinery in working conditions needs information regarding various refrigeration techniques that are present to make the right decisions. These systems work on principles and are used for particular purposes. Let us talk about four types of refrigeration systems which one should know.

Vapor Compression Refrigeration System

The vapor compression refrigeration system is used most often for air conditioning cooling and other types of commercial and industrial refrigeration uses due to its efficiency and versatility to meet cooling requirements.

What Is the Vapor Compression Refrigeration System?

The fundamental operation of a vapor compression refrigeration system is to conduct the flow of heat from a place to another using the aid of a refrigerant through mechanically compressing the refrigerant and exposing it to fluctuating conditions of pressure and temperature in such a way as to create the needed cooling effect.

How It Works?

Refridgerant is mechanically compressed to high-pressure gas, expanded to cold low-pressure liquid. It absorbs heat in the evaporator, creating a cooling effect. It returns to the compressor as hot gas, increasing pressure and temperature. It enters the condenser, releasing heat and condensing to high-pressure liquid. Pressure and temperature are reduced by the expansion valve, starting the cycle again. This process is used for the extraction of heat and cooling.

What Are Its Main Constituents?

Some very important constituents need to be present in order for this process to run nicely and efficiently;

Refrigerant

The refrigerant is a natural component of the refrigeration system, which absorbs heat and releases heat as it transfers from liquid state to gas form. In refrigeration applications that operate in the range of +5°C to 30°C. Some man-made fluorinated compounds that fall under the category of the HFCs are very common in the majority of the small domestic and commercial refrigerators due to their excellent performance in cooling objects. R 404A is one of the most common refrigerants found in commercial cooling devices because it can efficiently operate in the range of temperatures.

Compressor

The compressor is the central part of the system that increases the pressure and temperature of the vapor by an energy-driven process. The low-pressure vapor is compressed to a high-pressure condition to facilitate heat rejection in the condenser unit. Different compressors such as reciprocating and screw compressors are utilized based on considerations such as the type and size of cooling load.

Condenser

The condenser is a type of heat exchanger which allows the hot and high pressure of the vapor refrigerant to transfer its energy to the surrounding atmosphere. And recondense to a high pressure liquid form again The process of heat release is a crucial component of the refrigeration cycle.

Evaporator

The evaporator is also used as a heat exchanger and generally located in the cooling space where it cools the environment by taking heat from it with low pressure liquid refrigerant that evaporates into low pressure gas by undergoing an evaporation process in the evaporator unit coils.

Expansion Valve

Expansion valve or throttling device regulates the flow of high pressure refrigerants to the evaporator by decreasing its pressure and temperature in a bid to achieve maximum heat absorption in the evaporator.

Why It Is Used Generally?

The vapor compression refrigeration system is used everywhere because it is efficient and reliable in obtaining various degrees of temperatures in various environments – from common household freezers to huge industrial air conditioning systems – and thus it is a ubiquitous and widely used technology because it is versatile and is constantly undergoing technological improvement that still keeps it at the top.

Absorption Refrigeration System

The absorption cooling system offers an alternative to the traditional mechanical compression process with a new mechanism for creating cooling effects. It is based on materials that can absorb and release refrigerants under various conditions.

What Is the Absorption Refrigeration System?

In an absorption cooling system of compressing the refrigerant using a mechanical compressor to create a cooling effect, a process involving a refrigerant and an absorbent is utilized. The system uses heat as the energy source which can be beneficial during instances of high waste heat or low electricity availability.

How Does It Differ from Compression Systems?

Pressure rise differs in refrigerants: vapor compression uses a mechanical compressor, and absorption systems use thermal and chemical processes.

What Are Its Main Parts?

Major components of an absorption cooling system are;

Absorber

The absorber is where the pressure refrigerant vapor from the evaporator is absorbed by the absorbent solution and creates a strong absorbent refrigerant mixture.

Generator (Desorber)

The machine has a source of heat, say steam or gas used to heat the absorbent refrigerant solution and discharge the high pressure refrigerant vapor in the process.

Condenser

Likewise, the vapor compression system works to cool the pressure refrigerant vapor and condense it into high-pressure liquid.

Evaporator

The evaporator works the same way as when a vapor compression system is used by taking heat from the area to be cooled as the low-pressure refrigerant is in evaporating state.

Expansion Valve

The control valve lowers pressure and temperature of the high-pressure refrigerant before the evaporator.

Pump

The pump helps in the flow of the absorbent solution from the absorber to the generator.

Where Is It Generally Used?

Absorption cooling systems are also found to be used in businesses and industries where theres waste heat to be utilized effectively. They’re also employed in recreational vehicles and where there needs quiet operation since they have fewer components compared to vapor compression systems.

Evaporative Cooling System

Evaporative cooling is a natural, energy-efficient air cooling process by the cooling effect of water evaporation in dry climates.

What Is the Evaporative Cooling System?

A system based on the fact that water, when evaporating to produce air, removes heat from the surrounding and therefore cools air without refrigerants, such as in compression or absorption systems.

How Does It Cool Without Refrigerant?

The process of cooling is done when water is evaporated into the air directly by flowing over a surface like water-logged pads. When the water evaporates from the liquid to the gaseous form by the process of evaporation, it pulls heat energy from the air flowing over the surface due to which air cooling takes place. The cool and moist air is then blown within the room for producing cooling effects.

What Are Its Major Components?

The main constituents of an evaporation-based cooling system are;

Water Source

A water source is necessary to maintain the humidness of the cooling surface or pads.

Evaporative Pads or Surface

These surfaces are saturated, providing a path for hot airflow which enables water to evaporate.

Fan or Blower

A blower of air is utilized to suck air, which circulates the cooled air within the system.

Water Distribution System

Giving an equal quantity of water across the pads brings about an even cooling effect.

When Is It Most Effective?

In arid conditions where the air is far from humid or even possesses low humidity levels evaporative cooling works best, because water quickly evaporates, causing a huge reduction in temperature. While in humid places, like tropical regions evaporate less water evaporates because the air is saturated with water content causing minimal or no cooling effect.

Thermoelectric Refrigeration System

Solid-state refrigeration technique known as thermoelectric cooling or use of the term “cooling” provides an alternative means of achieving cooling effects without the need for traditional refrigerants or mechanics based on the power consumption of the thermoelectric effect.

What Is the Thermoelectric Refrigeration System?

A thermoelectric refrigerator exploits the effect that passing an electric current through a couple of extremely dissimilar conductive materials (semiconductors) leads to heating at one junction and emission at another junction; hence a temperature gradient.

How Is It Powered With the Peltier Effect?

When current flows, through a thermoelectric module it will cool one end of the module (heat absorption). The second side to be heated (to emit heat). By reversing the flow direction, you can cause what side is warming up and what side is cooling to adapt. How much heat will be transferred and the temperature difference that you will be able to attain will rely on the strength of the electric current as well as on the type of the materials that have been put on the thermoelectric module.

What are the Components that Make It Perform the Function?

The key elements of a thermoelectric cooler system are;

Thermoelectric Modules

The heart of the system is the thermocouples. A pair of P type and N type semiconductor material. Electrically series and thermally parallel.

Heat Sinks

Heat sinks are placed on both cold side of the thermoelectric module to help dissipate hot side heat and to provide means for cold side heat absorption to improve the efficiency of the system.

Power Supply

In order to power the thermoelectric modules, you will need a DC power source to supply the electric current.

Why is it suitable for small scale cooling?

Thermoelectric cooling systems are particularly suitable for small scale cooling applications that require temperature control and miniaturization but care more about reliability than other factors like energy efficiency compared to conventional vapor compression systems in large cooling systems.

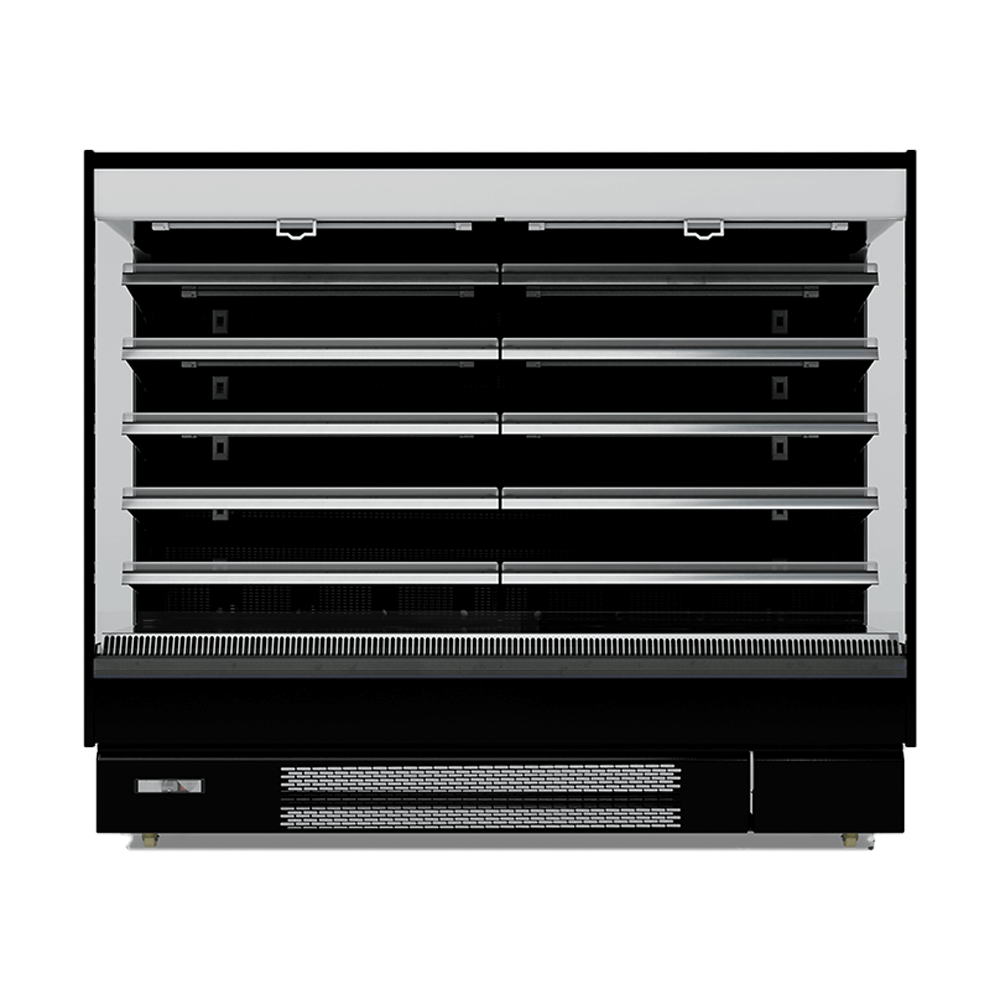

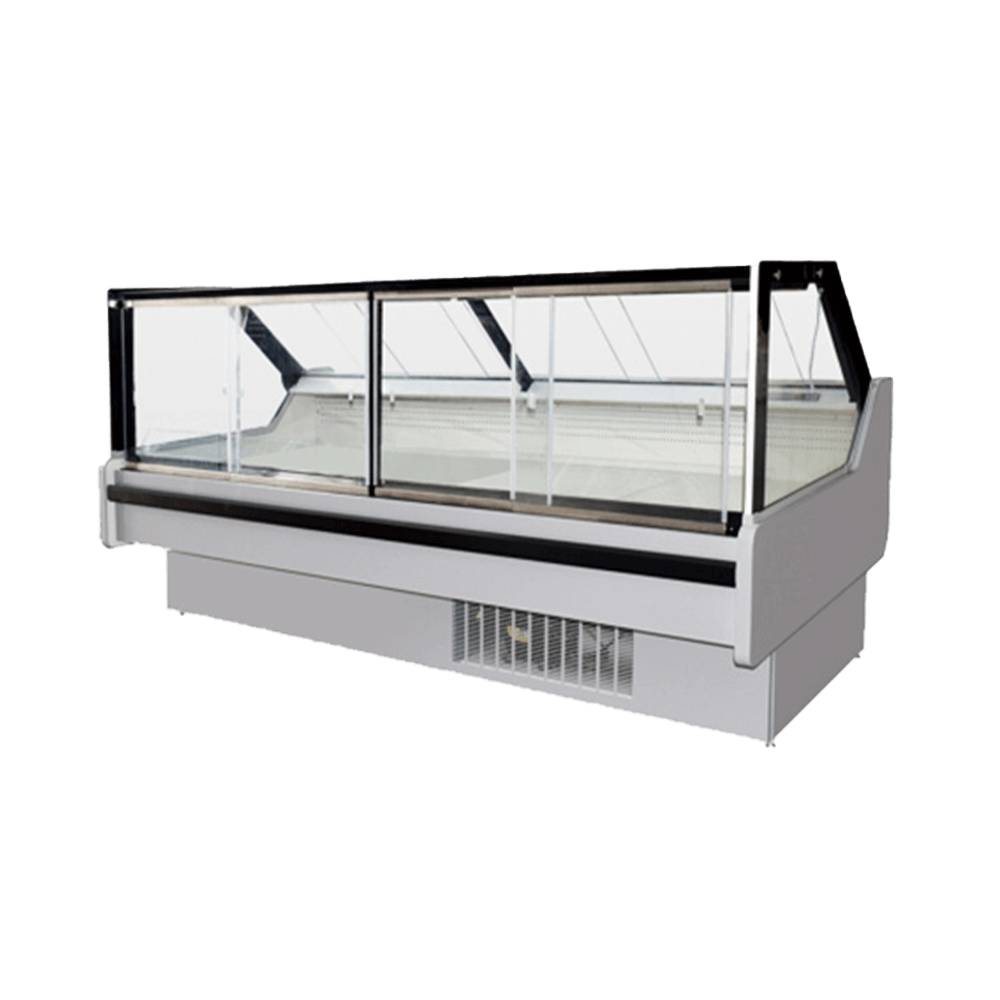

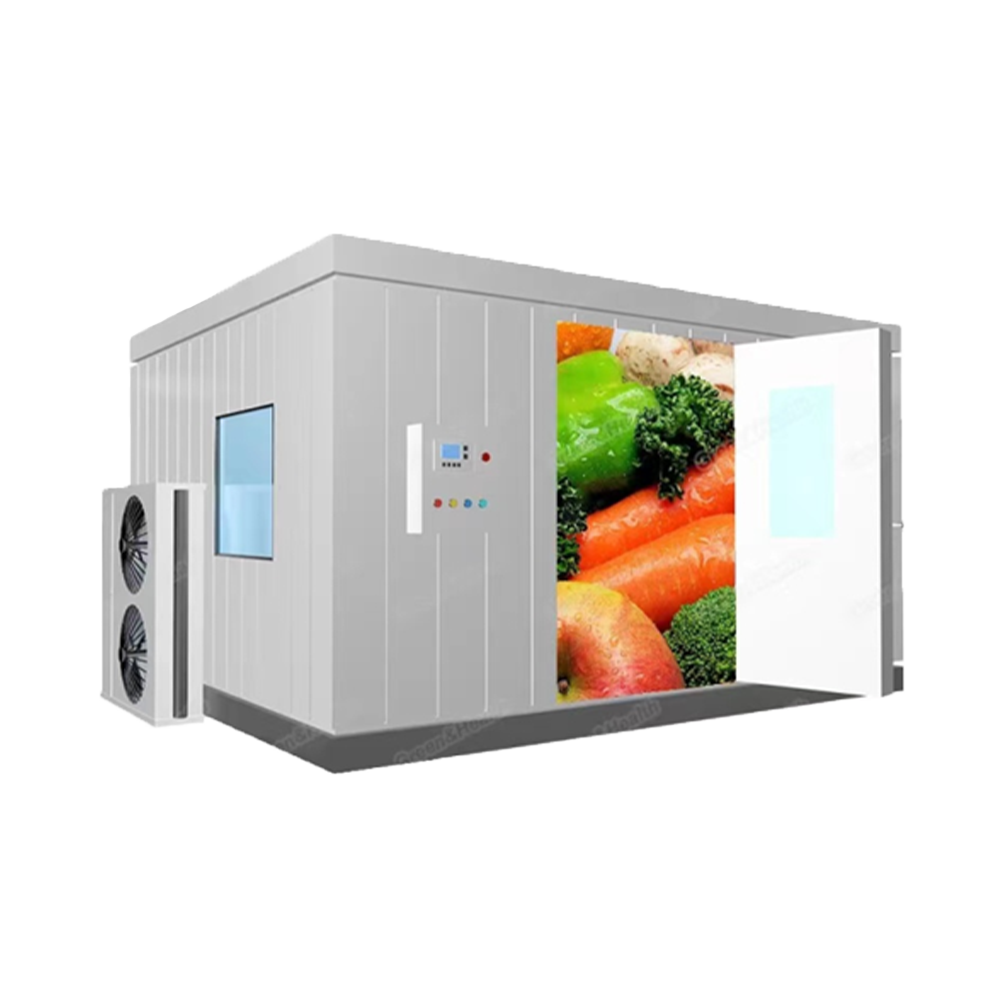

Why select Shandong Create Refrigeration as your supplier?

Select Shandong Create Refrigeration Co., Ltd. for trusted commercial refrigeration supplies. Established since 1999 with 25+ years of experience, their factory manufactures more than 23,000 units each year for hospitality, retail, and food processing sectors. They provide bespoke designs to suit individual requirements. CE, GS, CCC, and other accreditations guarantee that their products comply with international standards of safety and are applied internationally in North American, European, and Asian markets. They also provide OEM solutions for well-known brands, thus they possess strong manufacturing capacity. Business with them guarantees access to diversified products and a global customer base.

FAQs

Q: What happens to food when it is exposed to light in a refrigerator?

A: Light has an impact on the quality of food, such that solid door systems (as opposed to glass) preserve texture and flavor.

Q: Why are absorption systems well-suited off-grid?

A: They can use other heat sources like solar energy or propane, reducing the reliance on electricity.

Q: What are some common signs that a commercial fridge could do with maintenance work?

A: Signs that your business fridge needs maintenance: 1) Fluctuations in temperature. 2) Excessive frost. 3) Unusual noises. 4) Water leaking. 5) Running constantly without switch-off. 6) Sudden spike in utility bill. Repair these to prevent greater problems and costly repair.